Introduction

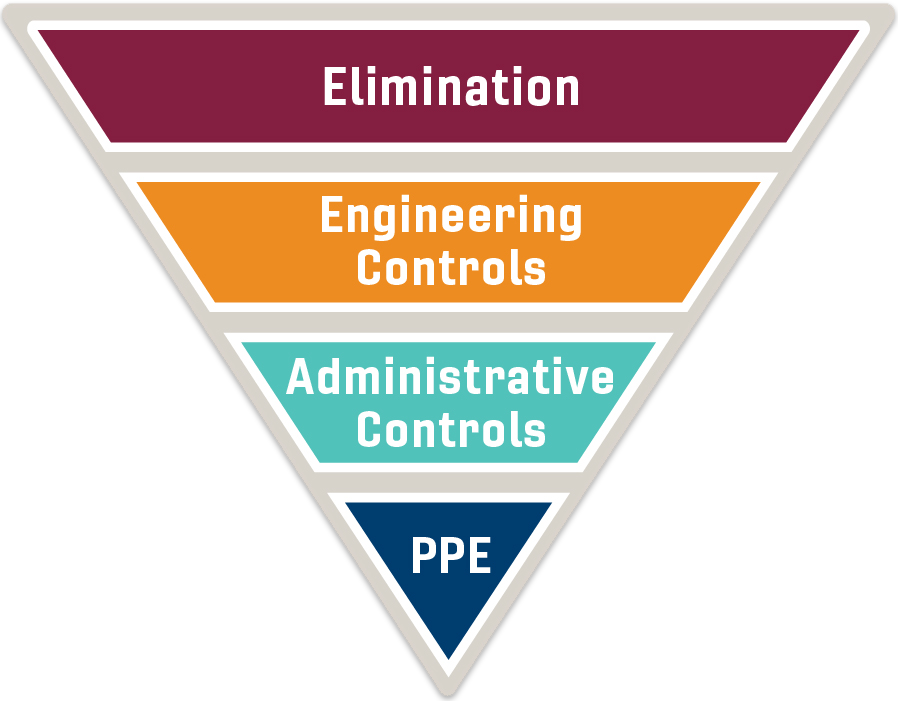

Hierarchy of Controls to Mitigate Risks

When evaluating risks in the workplace, and specifically in transportation, mitigating daily hazards requires a layered approach. This may include, for example, operating vehicles with the latest safety features, wearing seatbelts, and avoiding speeding. Some tools exist that encourage drivers to practice safe behaviors, such as automatic emergency braking, seat-belt wearing reminders, and roadway signage. A similar range of layered solutions exists to mitigate the effects of COVID-19 in transportation.

The goal in addressing hazards is to eliminate them. When it comes to COVID-19 and other viruses, one of the best tools available is vaccines. However, other tools can help reduce transmission and benefit worker safety and health until elimination can be attained. These tools fit into two classifications: engineering controls and administrative controls. Researchers at VTTI have collected and organized information to assist transportation fleets and agencies in developing a layered approach to mitigate COVID-19 and other future viral risks. First, some universal tools are provided below on vaccines, administrative controls, and engineering controls, followed by detailed information on some categories of engineering controls to support transportation workers and the public they serve.

For more information on workplace practices and strategies to prevent exposure and infection, see the OSHA website "Protecting Workers: Guidance on Mitigating and Preventing the Spread of COVID-19 in the Workplace."

Vaccination

Workers should consider the risks of exposure to COVID-19 and the benefits that vaccines can provide. Following are some important hazard considerations for the operators and passengers of these modes of transportation:

- Personal Vehicle Commuters: Drivers and passengers experience prolonged interactions during daily commuting activities

- Service/Utility/Energy Crews: Drivers and crew members experience interactions during daily transport between service activities, occasionally (e.g., weekly/monthly) crew members may experience prolonged interactions during worksite relocation trips

- Taxi/Rideshare: Frequent interactions among drivers and passengers occur in the vehicle for moderate periods of time, interactions with other workers during rest breaks may occur daily

- Transit

- Bus Operators: Frequent interactions occur among drivers and multiple passengers in the vehicle during customer service activities, interactions with other workers during rest breaks may occur daily

- Rail Operators: Interactions among drivers and multiple passengers during direction transfers, interactions with other workers during rest breaks may occur daily

- Service & Security: Frequent interactions among personnel and multiple passengers in vehicle/rail-car during customer service and security activities, interactions with other workers during rest breaks may occur daily

- Truck Drivers: Prolonged interactions with another team driver in the vehicle, interactions with other workers during customer service, interactions with the public during fueling and rest breaks occur daily

Key point: Vaccinations reduce the spread of COVID-19 and improve worker health outcomes if they do contract COVID-19.General information and resources are available on Vaccines for COVID-19, covering FAQs, myths, booster shots, and recommendations for all ages.

Administrative Controls

Engineering controls, discussed below, are recognized as highly effective methods at reducing exposure, however administrative controls remain effective. Administrative controls change the way people interact, depend on compliance of the correct procedure by workers, and are best when combined with other controls. Guidance resources on administrative controls can be found at CDC websites on Types of Masks & Respirators, Hand Washing, and Cleaning & Disinfecting. Guidance includes:

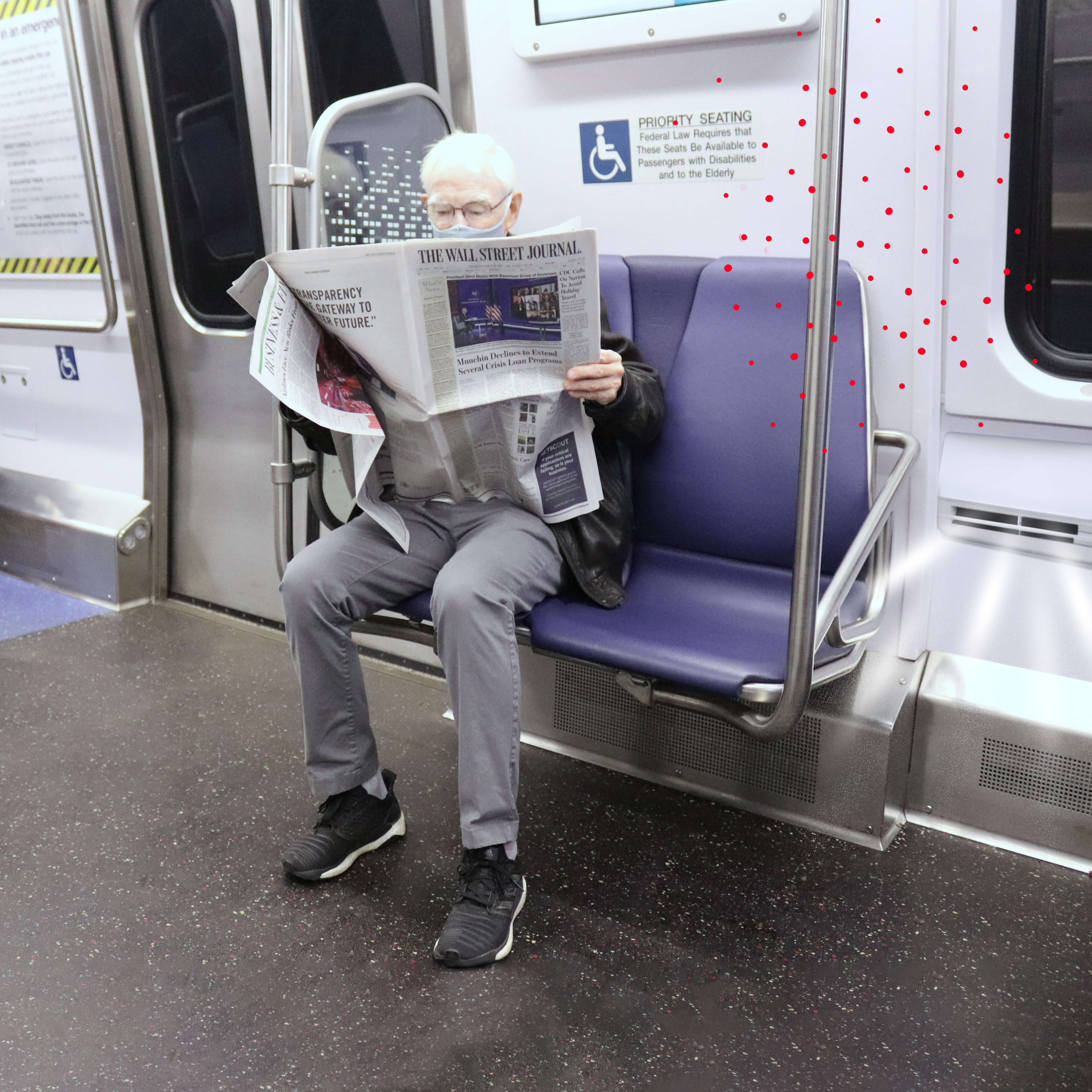

- Masks: Masks reduce the chance of viral transmission via larger droplets. Additionally, a properly fitted mask reduces the chance of viral transmission via smaller particles. 1 2

- Physical Distancing: Physical distancing reduces the chance of viral transmission from an infected person.

- Hand Washing: Hand washing can be considered a form of routine personal cleaning. Washing your hands with soap and water for 20 seconds is the most reliable tool to prevent infection from surface contact. When washing is not possible, using hand sanitizer with at least 60% alcohol to clean hands is an effective alternative.

- Cleaning: Routine cleaning should be prioritized for high-touch surfaces at least once a day. Disinfecting surfaces used by someone who tested positive for COVID-19 within 24 hours is important. When disinfecting surfaces, use products from EPA List N to ensure effectiveness and always follow the instructions on the product label.

Key point: The benefits of mask-wearing are well-established and remain an important tool in any layered approach to preventing the spread of COVID-19, especially while indoors around groups and in communities of high rates of transmission.

Engineering Controls

Engineering controls isolate people from the hazard and do not rely on individual behaviors. Engineering controls can be applied to effectively and consistently support the health of transportation workers and mitigate the behaviors of others they may interact with around the vehicle or in their workplaces. The following considerations should be made when evaluating tools for each mode of transportation.

- Transit: Bus operators and bus/rail onboard service and security personnel and passengers interact in close spaces for exposure periods of 15 minutes or more with a large and constantly rotating number of occupants. The air space of these vehicles/rail-cars can be manually exchanged through opening doors and windows as part of regular service, but this impact can be limited in some sections of the vehicles/rail-cars. Management of the existing HVAC and exterior openings can be effective in the near term, while considering further term enhancements to ventilation system filters and air treatment that are presented here. Rapid and continuous filtering and treatment controls should be considered due to the rapid turn-over and large number of occupants in transit. Investing in innovative new bus and HVAC architectures is important in the long term but is beyond the scope of this information.

- Taxi/Rideshare: As with transit, taxi and rideshare drivers and occupants experience high rates of turnover in the number of occupant interactions per hour. However, the combination of existing HVAC and smaller cabin air space in these vehicles lends these modes to simple filtration and treatment enhancements and manual air exchange solutions (e.g., opening doors or windows between service activities).

- Commuters and Crews: Unlike in taxi/rideshare transit modes, commuters and crew who regularly ride and work together have options for contact tracing and communication about health status if turnover rates are low. Also, the vehicles and lightweight trucks operated by commuters and crews have existing HVAC and smaller cabin air spaces that lends these modes to simple filtration and enhancements, as well as manual air exchange solutions (e.g., opening doors or windows).

- Truck: These vehicles are operated by personnel—often by team drivers—that regularly work together and can trace and communicate health status. However, in some applications (e.g., over-the-road) these vehicles may rarely return to their point of origin. Therefore, these personnel may be pressured by cargo delivery deadlines and preventative costs (e.g., hotel) to continue operating. In addition to this pressure, these vehicles have larger cabin air spaces that are more complex to ventilate and vehicles are only stopped a few times during the day. Therefore, these vehicles may require more complex solutions.

Key point: One important tool in any layered approach identified by the CDC is ventilation. The American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) produced guidance for implementing ventilation in buildings that is generalizable to transportation systems. Safe and effective tools (e.g., filtration, air sanitization, and barriers) are being discovered and new applications are being validated to reduce exposure to air and surface transmitted pathogens. The CDC recommends using multiple mitigation strategies, including improvements to building and transportation ventilation systems. The CDC has provided an interactive tool for homeowners to help decrease the level of virus particles in homes.

The following information on engineering controls is provided to educate readers on a set of available tools rather than to endorse any specific technology or product. Readers should carefully consider the latest research and information on the effectiveness, application, and possible unintended consequences of each tool prior to implementation. Examples of applications where implementation has been attempted are provided below.

- Technology description: MERV 14 filter

- Type: Air filtration

- Application: Rail car ventilation system

- Effectiveness: MERV-14 is rated with at least 90% effectiveness and MERV-13 is rated with at least 85% effectiveness for particles between 1 to 3 microns (compared with MERV-8 at 20% effectiveness for 1 to 3 microns) 3

- Safety: No known risk

- Notable: One important factor in rail HVAC system performance, identified by engineers at a major mass transit agency, is the fan type (i.e., squirrel cage) where voltage is not severely affected by increased pressure drop and reduced air flow. 4

- Technology description: Triethylene glycol (TEG), dosing self-monitored

- Type: Sanitize air

- Application: May be most effective in closed ventilation systems but activation times are promising for open ventilation systems; public messages (signs) are recommended with implementation

- Effectiveness: Kills 98% of SARS-CoV-2 on airborne particles 5

- Safety: Temporarily approved in emergency exemption by EPA on Jan. 15, 2021, for indoor spaces where social distancing and mask wearing can be challenging as well as in health care facilities, intrastate transportation, food processing, and indoor spaces for essential activities in certain states; TEG can irritate some sensitive individuals 7

- Notable: Related to many years of application in theatrical fog

- Technology description: Bipolar ionization

- Type: Sanitize air and surface

- Application: Closed ventilation system

- Effectiveness: 99.4% effective in 30 minutes on SARS-CoV-2 (COVID-19) virus on surfaces 8; 65.4% effective in 30 minutes on SARS-CoV-2 (COVID-19) virus in air 9 based on privately funded studies

- Safety: Some devices claim to control voltage to enable ozone-free operation

- Notable: In-room ion density is dependent on a variety of factors, including proximity of the ionizing equipment to the occupied space, air flow rates, and path of the ductwork; bipolar ion treatment of other viruses has been measured to be 1.7 times more effective than unipolar ion treatment. 10

- Technology description: Photocatalytic non aqueous hydrogen peroxide gas system combined with UV irradiation

- Type: Sanitize air and surface

- Application: Closed ventilation systems

- Effectiveness: SARS-CoV-2 73% inactive at 15 mins., 93% at 60 mins., 98% at 4 hours based on privately funded studies 11

- Safety: Ozone released is 0.02 ppm (safe limit of 0.1 ppm, OSHA) 12 Hydrogen peroxide released is 0.05 ppm (safe limit of 1 ppm, OSHA) 13

- Notable: Private testing performed in coach bus and field testing performed in transit bus. 14

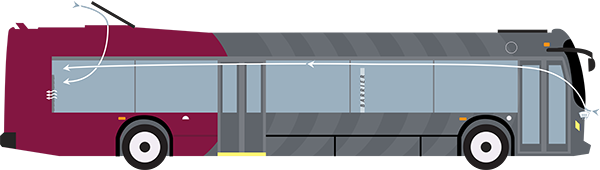

- Technology description: Pressure barrier in transit bus passenger area

- Type: Dilution through improved airflow management

- Application: Exposure reduction for bus operator when installed on buses with rear-mounted HVAC returns; open ventilation system; two-door vehicle

- Effectiveness: Limited field testing shows effective bus operator workstation zone separation of interior air when combined with optimal window/hatch openings due to mitigating exterior airflow around vehicle 15

- Safety: No known risks

- Notable: Significantly improves physical distancing between bus operators and passengers; optimal implementation with rear door touchless fare system

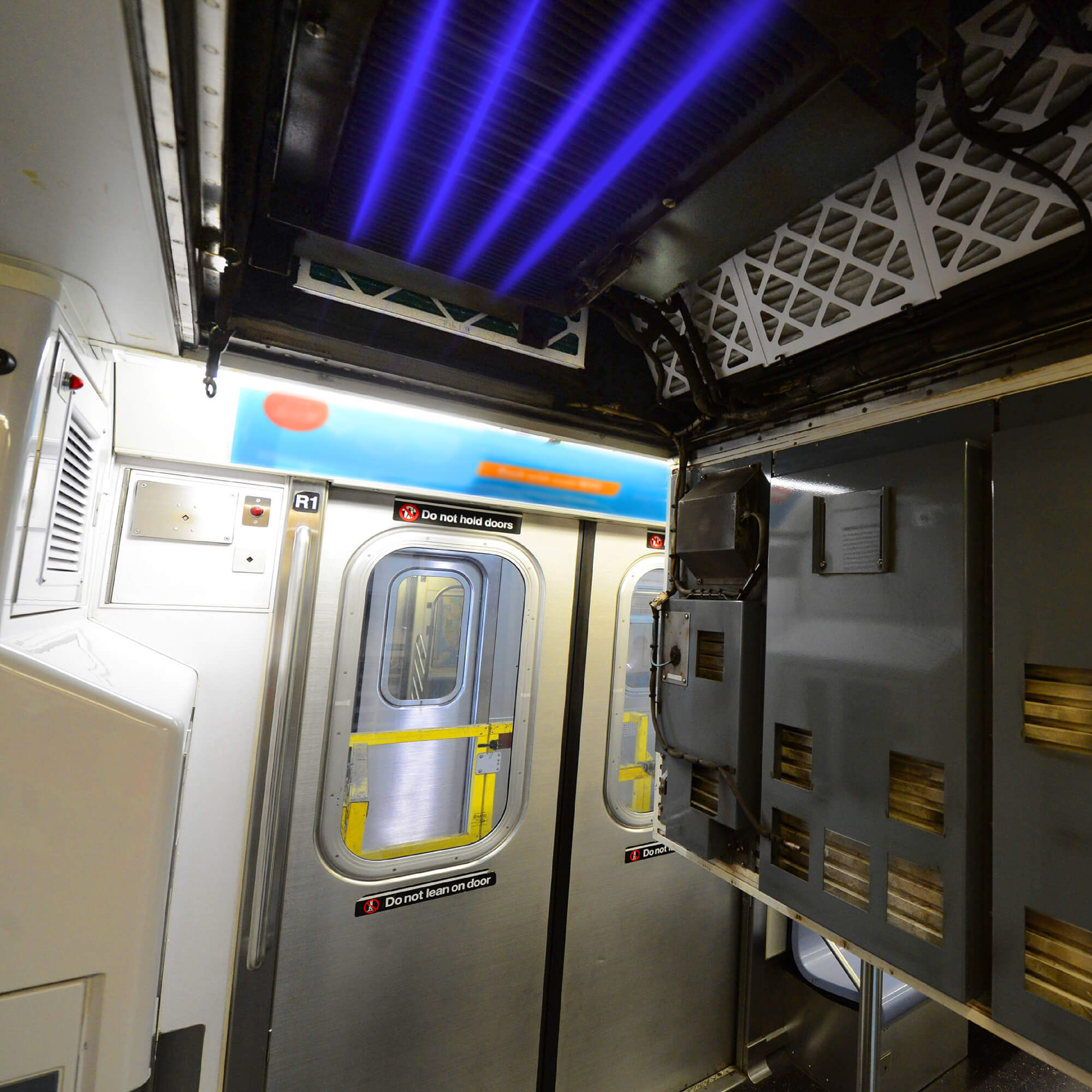

- Technology description: UV-C (254 nm) lamp

- Type: Sanitize surface and air

- Application: Open or closed ventilation systems

- Effectiveness: Greater than 99.99% inactivation of SARS-CoV-2 within 5 minutes of application at 12-foot distance 16; eliminated 99.99% of SARS-CoV-2 in a single pass at an airflow rate of 500 feet per minute based on privately funded studies 17

- Safety: UV-C radiation can be harmful to skin and eyes if not contained in closed space

- Notable: Deployment exists in field testing on rail-car HVAC condenser units 18

- Technology description: Heating and A/C ventilation roof-mounted units

- Type: Dilution

- Application: Open ventilation system

- Effectiveness: Can direct air flow to passengers up to 4 meters away (40-foot bus: 12 meters); 100% fresh air; no measurable pathogen impact

- Safety: No known risks

- Notable: Can also reduce thermal (hot/cold) exposure for personnel

Project Contact

Andrew Krum

- akrum@vtti.vt.edu

- 540-231-1500

- 3500 Transportation Research Plaza

Blacksburg, VA 24061